Retrospective® 75 Duffel Bag for travel, sports, and adventure

MORE INFORMATION

<ul>

<li>Antique plated metal hardware</li>

<li>Wide zippered opening provides access to main compartment</li>

<li>75 liters of total capacity</li>

<li>Large zippered pocket for easy access to essentials</li>

<li>Lockable zipper sliders on main compartment (lock sold separately)</li>

<li>Robust carry straps with leather grips</li>

<li>Removable shoulder strap</li>

<li>Padded removable shoulder strap with

non-slip silicone</li>

<li>Thick webbing grab-handles on all four sides</li>

<ul>

<strong>Interior:</strong>

<ul>

<li>P300D two-tone twill ripstop liner</li>

<li>3-ply bonded nylon thread</li>

</ul>

<br>

<strong>Exterior:</strong>

<ul>

<li>Durable water-repellant (DWR) coating</li>

<li>Sand-washed 100% cotton canvas</li>

<li>YKK® RC Fuse (abrasion-resistant) zippers</li>

<li>Antique plated metal hardware</li>

<li>Ribbed nylon webbing</li>

<li>Full-grain Dakota leather</li>

<li>3-ply bonded nylon thread</li>

</ul>

If you are not completely satisfied with our product, you can return it unused within 30-days for a full refund less shipping costs. Refunds will not be issued until the product is received and inspected to insure that it contains all the parts and is clean and unused. Note that we do not pay for shipping to have you return it to us.

At Think Tank, we build our products for the daily impacts of travel and demands of working professionals over extended periods of time. We build many of our products with user replaceable parts to keep your bag going for years.

Learn how QUALITY EQUALS LONGEVITY, so your product doesn't end up in the landfill.

SPECIFICATIONS

-

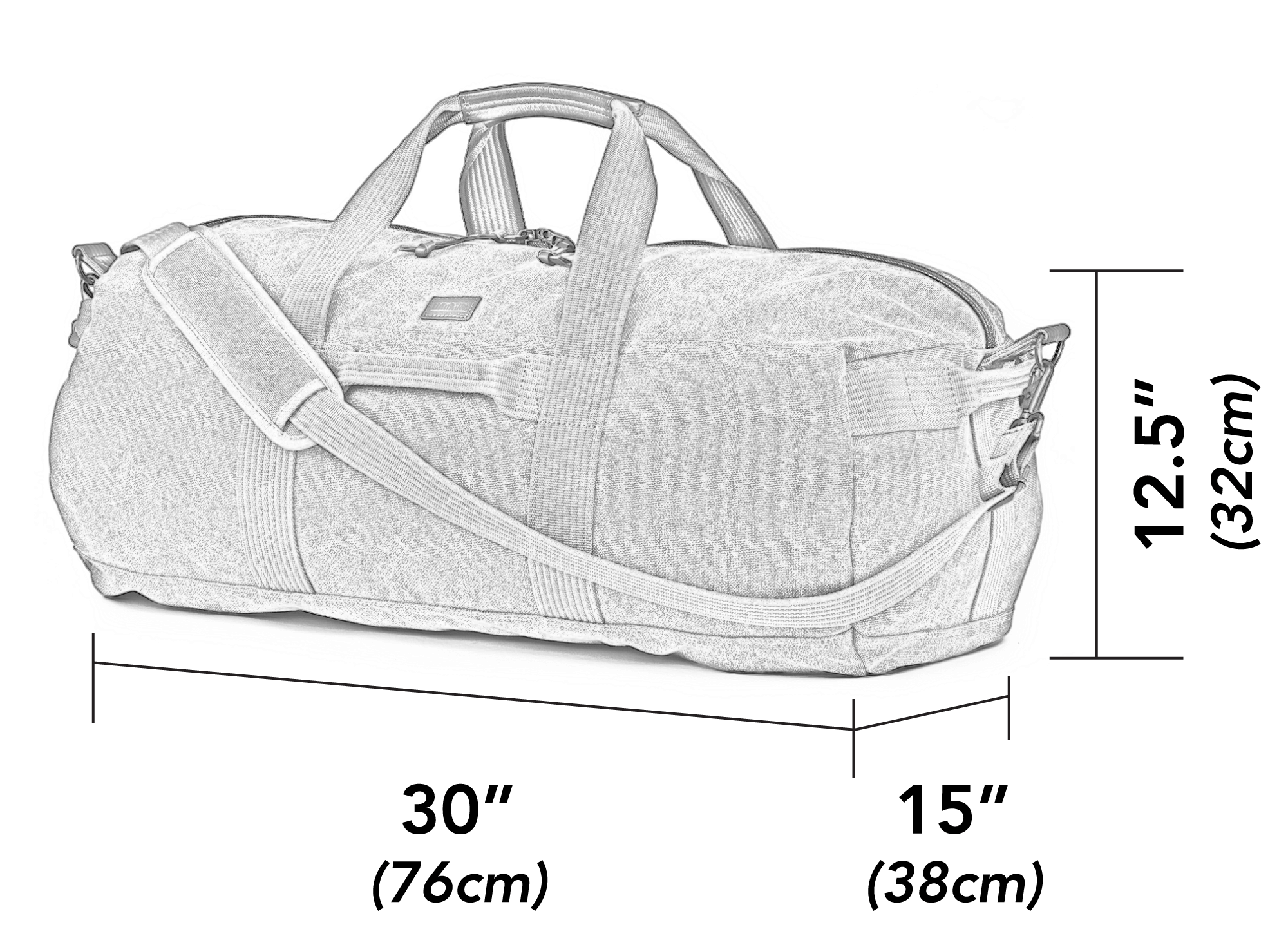

<strong>Exterior Dimensions:</strong><br>

30” L x 15” W x 12.5" H (76 x 38 x 32 cm)<br><br>

<strong>Capacity:</strong><br>

75 Liters<br><br>

<strong>Weight:</strong><br>

3 lbs. 7 oz (1.57 kg) including all accessories

WHAT FITS IN THIS BAG?

75 liters of clothing, camping gear, sports equipment, etc.

customer photos

IN THE FIELD

<b>Ian Spanier</b>

https://www.instagram.com/ianspanier/

https://www.facebook.com/ianspanierphoto

https://twitter.com/ianspanierphoto

https://www.ianspanier.com/